Ukwengeza ubuhlalu beglasi obungenalutho emikhiqizweni yerabha kungaletha izinzuzo eziningi:

1, Ukunciphisa isisindo

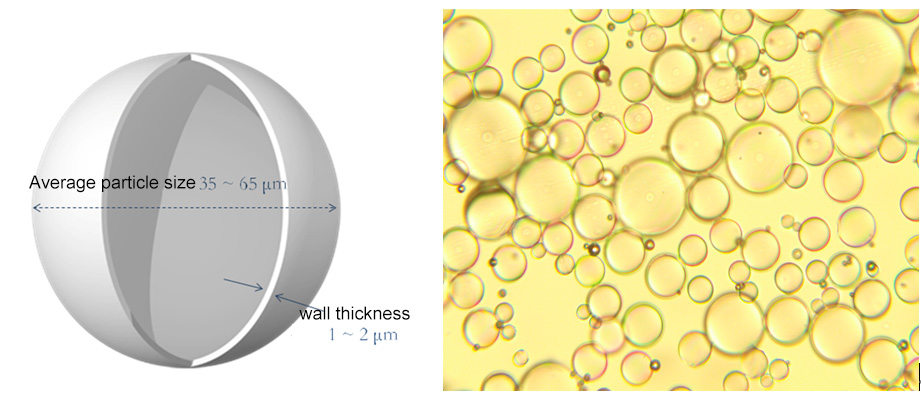

Imikhiqizo yerabha iphinde ibheke esiqondisweni esilula nesiqinile, ikakhulukazi ukusetshenziswa okuvuthiwe kwezinyawo zerabha ze-microbeads, kusukela ekuxineni okuvamile okungu-1.15g/cm³ noma ngaphezulu, engeza izingxenye ezi-5-8 ze-microbeads, ezincishisiwe zibe yi-1.0g/cm³ (eyaziwa ngokuthi “ukuntanta emanzini”), kukhona izinga elithile lamandla e-R & D amakhasimende ngokungeza ama-microbeads kuzoba ukuminyana okungu-0.9 noma ngisho no-0.85g/cm³, okunciphisa kakhulu ukuminyana kwerabha, izicathulo kanye nesimo esifanayo ngaphambi kokunciphisa isisindo okungu-20% noma ngaphezulu. Njengamanje, amanye amakhasimende anekhono elithile le-R & D azokwenza ukuminyana kube ngu-0.9 noma ngisho no-0.85g/cm³ ngokungeza ama-microbeads, okunciphisa kakhulu ukuminyana kwerabha, futhi isisindo sezicathulo sizoncishiswa cishe ngo-20% ngaphansi kwesimo esifanayo nangaphambili.

2, Ukushisa kokushisa

Isakhiwo esingenalutho sobuhlalu beglasi obungenalutho sinikeza ubuhlalu ukuhanjiswa kokushisa okuphansi, njengoba isigcwalisi sokugcwalisa ukuhanjiswa kokushisa okuphansi esengezwe ezintweni zerabha singadlala umphumela omuhle kakhulu wokufudumala, njengakuma-thermal insulation pads, amabhodi okushisa okushisa kanye neminye imikhiqizo esetshenziswayo.

3, Ukumuncwa komsindo kanye nokunciphisa umsindo

Ngaphakathi kwama-glass beads angenalutho kukhona igesi elincane, amaza omsindo kule ngxenye azobuthakathaka, ngesilinganiso esithile sokwengeza ukuze adlale umphumela omuhle kakhulu wokumuncwa komsindo nokunciphisa umsindo.

4, ukuzinza okuhle kobukhulu

Izinto eziyisisekelo zobuhlalu ziyingilazi ene-coefficient ephansi yokwanda kokushisa, ukuzinza okuhle kobukhulu uma kushaywa ukushisa, okungeziwe ezintweni zerabha kuzonikeza umkhiqizo ukuzinza okungcono kobukhulu.

Iziphakamiso zokusetshenziswa ekucutshungulweni:

1, imishini yokucubungula imikhiqizo yerabha ngokuvamile iwumshini wokuhlaziya oqinile, ovulayo, umshini wokukhipha isikulufa esisodwa, njll., ngoba ubuhlalu buyingilazi, udonga lungolwama-particle aqinile, amandla okugunda angomshini azophulwa kancane, ubuhlalu buzolahlekelwa ukusebenza kwawo okuyingqayizivele ngemva kokuphuka.

2, ubuhlalu beglasi obungenalutho bunezinhlobo ezahlukene kanye nemingcele ehambisanayo, ngokuya ngemishini ehlukene kanye nezidingo zomkhiqizo ukukhetha imikhiqizo yobuhlalu efanele kubaluleke kakhulu, iSt. Leite itusa ukusetshenziswa kwe-HL38, HL42, HL50, HS38, HS42 emikhiqizweni yerabha.

3, uma isetshenziswa emshinini wokucwenga, kukhona i-rotor ekuchebeni kwezinto zerabha, ubuhlalu abunakugwenywa ngamandla okucheba, ukuze ngangokunokwenzeka kuncishiswe isikhathi sobuhlalu ekucwengisisweni, kunconywa ukuthi kufakwe ekucwengisisweni kwakamuva ukuqinisekisa ukuthi ubuhlalu obungezwe ekucwengisisweni imizuzu engu-3-5 bungahlakazeka ngokulinganayo; emshinini wokucwenga, isikhala se-roller kanye nesikhathi sokucwenga sokuchotshozwa kwama-beads kunomthelela omkhulu, kunconywa ukuthi isikhala se-roller singaphezulu kuka-2mm, isikhathi sokucwenga akufanele sibe side kakhulu; Amandla okucheba aphelele e-single screw extruder mancane, uma kuqhathaniswa, umthelela kuma-microbeads mncane, kunconywa ukwandisa izinga lokushisa le-extrusion ngo-5 ℃, ukunciphisa i-viscosity yezinto ezihambisana nokubumba kwe-extrusion, ukunciphisa ama-microbeads aphukile.

Isikhathi sokuthunyelwe: Julayi-21-2023