Ukwengeza ubuhlalu bengilazi obungenalutho emikhiqizweni yenjoloba kungaletha izinzuzo eziningi:

1. Ukunciphisa isisindo

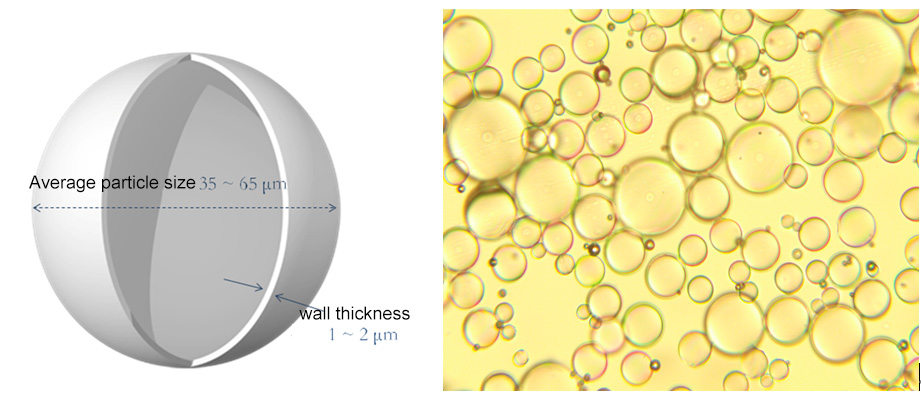

Imikhiqizo yenjoloba nayo ibheke ekuqondeni okungasindi, okuhlala isikhathi eside, ikakhulukazi ukusetshenziswa okuvuthiwe kwamasoli erabha amancane, kusukela kubuningi obuvamile obungu-1.15g/cm³ noma ngaphezulu, engeza izingxenye ezingu-5-8 zobuhlalu obuncane, obuncishiswe bungu-1.0g/cm³ (okwaziwa kakhulu ngokuthi “ elintanta emanzini”), kunezinga elithile le-R & D lamakhono amakhasimende ngokungeza ama-microbeads kuzoba ukuminyana kuka-0.9 noma ngisho no-0.85g/cm³, kunciphisa kakhulu ukuminyana kwenjoloba, izicathulo kanye nesimo esifanayo ngaphambi kokwehliswa kwesisindo. 20% noma ngaphezulu.Njengamanje, amanye amakhasimende anekhono elithile le-R & D azokwenza ukuminyana kube ngu-0.9 noma ngisho kube ngu-0.85g/cm³ ngokwengeza ubuhlalu obuncane, okunciphisa kakhulu ukuminyana kwenjoloba, futhi isisindo sezicathulo sizoncishiswa cishe ngo-20% ngaphansi okufanayo. isimo njengakuqala.

2, Ukushisa kokushisa

Isakhiwo esingenalutho sobuhlalu bengilazi obungenalutho sinikeza ubuhlalu ukuguquguquka okuphansi kwe-thermal, njengoba isigcwalisi esiphansi se-thermal conductivity esingezwe ezintweni zenjoloba singadlala umphumela omuhle kakhulu wokushisa oshisayo, njengaku-thermal insulation pads, amabhodi okushisa ashisayo neminye imikhiqizo esetshenzisiwe. .

3, Ukumuncwa komsindo nokunciphisa umsindo

Ngaphakathi ongenalutho ingilazi ubuhlalu igesi elincanyana, amagagasi omsindo kule ngxenye kuyoba buthaka, ngenani elithile kwalokho ukudlala umphumela omuhle kakhulu ukumuncwa umsindo kanye nokunciphisa umsindo.

4, Ukuzinza okuhle kwe-dimensional

Izinto eziyisisekelo zobuhlalu ziyingilazi ene-coefficient ephansi yokwanda okushisayo, ukuzinza okuhle kwe-dimensional uma ibhekene nokushaqeka okushisayo, okungezwe kunto yenjoloba kuzonikeza umkhiqizo ukuzinza okungcono kobukhulu.

Iziphakamiso zokusetshenziswa ekucubunguleni:

I-1, imishini yokucubungula imikhiqizo yenjoloba ngokuvamile iyisicwengisisi esiminyene, isivuli, i-single-screw extruder, njll., ngoba ubuhlalu buyingilazi udonga oluyingxenye yezinhlayiya eziqinile, endimeni ye-shear force force izophulwa kancane, ubuhlalu buzolahlekelwa. ukusebenza kwayo okuyingqayizivele ngemva kokuphulwa.

2, ubuhlalu bengilazi obungenalutho bunamamodeli ahlukene kanye nemingcele ehambisanayo, ngokusho kwemishini ehlukene kanye nezidingo zomkhiqizo ukukhetha imikhiqizo yobuhlalu efanele kubaluleke kakhulu, u-St. Leite uncoma ukusetshenziswa kwe-HL38, HL42, HL50, HS38, HS42 emikhiqizweni yenjoloba.

I-3, uma isetshenziswa emshinini wokucwenga, kukhona i-rotor ku-shear ye-rubber material, ubuhlalu abukwazi ukugwenywa ngamandla okugunda, ngakho-ke ngangokunokwenzeka ukunciphisa isikhathi sobuhlalu ekucwengisweni, kunconywa ukuthi wengeze ukucwengwa sekwephuzile ukuze kuqinisekiswe ukuthi ubuhlalu obungezwe ekucwengisweni 3-5min bungahlakazwa ngokufanayo;emshinini wokucwenga, isikhala se-roller kanye nesikhathi sokucwenga sokuchotshozwa kobuhlalu kunomthelela omkhulu, kunconywa ukuthi isikhala se-roller> 2mm, isikhathi sokucwenga akufanele sibe side kakhulu;I-shear force yonke ye-screw extruder eyodwa incane, uma kuqhathaniswa, umthelela kuma-microbeads mncane, kunconywa ukwandisa izinga lokushisa le-extrusion ngo-5 ℃, ukunciphisa i-viscosity yento ewusizo kakhulu ekubunjweni kwe-extrusion, ukunciphisa ama-microbeads. ephukile.

Isikhathi sokuthumela: Jul-21-2023