Izinga lesikhunta se-FRP lihlobene ngokuqondile nokusebenza komkhiqizo, ikakhulukazi ngokwezinga lokuguqulwa, ukuqina, njll, okumele kudingeke kuqala.Uma ungazi ukuthi ungathola kanjani ikhwalithi yesikhunta, sicela ufunde amanye amathiphu kulesi sihloko.

1. Ukuhlolwa okungaphezulu kwesikhunta kwenziwa lapho kufika, futhi kuyadingeka ukuthi akufanele kube khona iphethini yendwangu ebonakalayo ebusweni;

2. Ubukhulu bejazi lejeli lokubunjwa bukhulu noma bulingana no-0.8mm, futhi ubukhulu bejazi lejeli ubukhulu besendlalelo sejazi lejeli ngemva kokuphulukiswa nokubunjwa, hhayi ubukhulu befilimu emanzi;

3. Akufanele kube khona ukufakwa kwe-resin ebusweni bekhoneni lesikhunta.

4. Umzimba oyinhloko wesikhunta, okungukuthi, izinga lokushisa lokushintsha okushisayo kwe-FRP laminate, ngokusho kwepharamitha ye-resin ka-2001 ≥110℃.

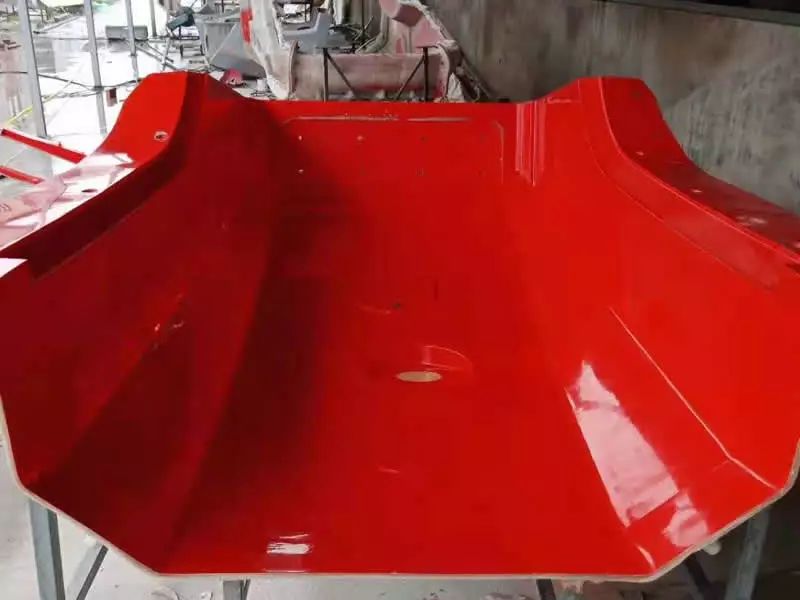

5. I-gloss kanye ne-flatness ebusweni bejazi lejeli kuyadingeka ukuze kufinyelele indawo ye-A-level.Ngendiza enezingqimba, i-silhouette ingaboniswa ngokucacile ngaphandle kokuguqulwa.

6. Izidingo zokuqina kobuso bejazi lejeli: inani elimaphakathi lokuqina kwebhasi lamaphoyinti okuhlakazeka ayi-10 akalwa ngomzimba wesikhunta likhulu kunama-35.

7. Isimo esiphezulu sesikhunta asidingi ama-bubbles ebusweni besikhunta, ama-bubbles angaphezu kwama-3 ngaphakathi kwe-1m2 yama-bubbles abonakalayo ku-gel coat kanye ne-mold laminate;awekho amamaki ebhulashi asobala, imihuzuko kanye nezimpawu zokulungisa ebusweni besikhunta, futhi angabi ngaphezu kwamaphinifa angu-5 ngaphakathi kwe-1m2 yobuso.A, angeke kube khona izendlalelo.

8. Uhlaka lwensimbi lwesikhunta lunengqondo, futhi kufanele lube nesakhiwo sohlaka jikelele.Iplatifomu yokubopha kufanele iqine futhi ingakhubazeki kalula;idivayisi ye-hydraulic ivula futhi ivale ngokushelelayo futhi ngokushelelayo, isivinini siyalungiseka, futhi umshini wokuhamba unikezwa, ongahlangabezana nezikhathi zokuvula nokuvala> izikhathi ezingu-1000 ekusetshenzisweni okujwayelekile.

9. Isikhunta siklanyelwe ngokwenqubo ye-vacuum yomkhiqizo, ubukhulu bomzimba oyinhloko buyadingeka ukuze bufinyelele ku-15mm, futhi ubukhulu be-flange yesikhunta buyadingeka ukuba bube ≥18mm.

10. Izikhonkwane zokumisa isikhunta ziyizikhonkwane zensimbi, futhi izikhonkwane nezingxenye ze-FRP kufanele zivalwe.

11. Umugqa wokusika wesikhunta uhlolwe ngokuqinile ngokwezinga lomkhiqizo.

12. Usayizi wokufanisa wesikhunta udinga ukunemba, futhi iphutha lokufanisa phakathi kwezingxenye ezifanayo kufanele libe ngu-≤1.5mm.

13. Impilo yesevisi evamile yesikhunta akufanele ibe ngaphansi kwamasethi wemikhiqizo engama-500.

14. Ukucaba kwesikhunta kungu-±0.5mm ngemitha yomugqa, futhi akufanele kube khona ukungalingani.

15. Zonke izilinganiso zesikhunta ziqinisekisiwe ukuthi zinephutha lika-±1mm, futhi akukho burr ebusweni be-laminate.

16. Ingaphezulu lesikhunta alivunyelwe ukuba libe neziphambeko ezifana nemigodi, amaphethini e-orange peel, imihuzuko ye-sandpaper, imifantu yezinyawo zenkukhu, njll., futhi i-arc kufanele ibe ukuguqulwa okushelelayo.

17. Isikhunta silashwa ngemva kokushisa okuphezulu kwama-80 ° C, futhi sidilizwa ngemva kwamahora angu-8.

18. Isikhunta asikwazi ukukhubazeka ngaphansi kwesimo se-exothermic esiphezulu esingu-90℃-120℃, futhi indawo engaphezulu ayikwazi ukuvela amamaki okushwabana, imifantu, nokungalingani.

19. Kufanele kube negebe elingaphezu kuka-10mm phakathi kohlaka lwensimbi kanye nesikhunta, futhi ukuhlangana kwemizimba emibili kufanele kuhlanganiswe nokhokho noma amabhodi anezingqimba eziningi anogqinsi olufanayo.

20. Ukuhlanganiswa kwesikhunta sokuhlukanisa akukwazi ukukhishwa, ukuklama kokumisa isikhunta kunengqondo, isikhunta siyakhululwa, ukusebenza komkhiqizo kulula, futhi isikhunta kulula ukusikhulula.

21. Ukucindezela okuphelele okungalungile kwesikhunta kungaphansi kwe-0.1, futhi ukucindezela kugcinwa imizuzu engu-5.

Isikhathi sokuthumela: Mar-22-2022