Ikhwalithi yesikhunta se-FRP ihlobene ngqo nokusebenza komkhiqizo, ikakhulukazi ngokwezinga lokuguquguquka, ukuqina, njll., okumele kudingeke kuqala. Uma ungazi ukuthi ungayibona kanjani ikhwalithi yesikhunta, sicela ufunde amanye amathiphu kulesi sihloko.

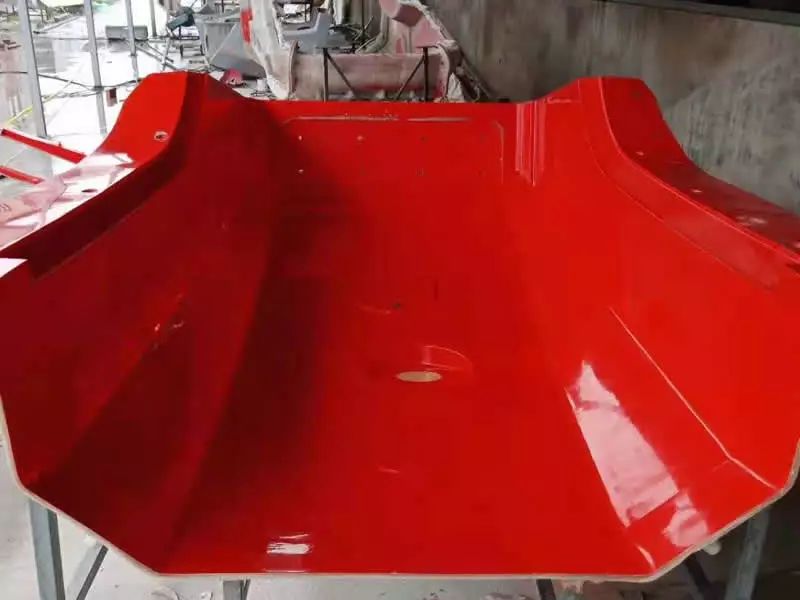

1. Ukuhlolwa kobuso besikhunta kwenziwa lapho sifika, futhi kuyadingeka ukuthi kungabikho iphethini yendwangu ebonakalayo ebusweni;

2. Ubukhulu bejazi lejeli lesikhunta bukhulu noma bulingana no-0.8mm, futhi ubukhulu bejazi lejeli bubukhulu besendlalelo sejazi lejeli ngemva kokulungiswa nokubumba, hhayi ubukhulu befilimu emanzi;

3. Akufanele kube khona ukufakwa kwe-resin ebusweni bekhoneni lesikhunta.

4. Umzimba oyinhloko wesikhunta, okungukuthi, izinga lokushisa lokuguquguquka kokushisa kwe-laminate ye-FRP, ngokusho kwepharamitha ye-resin ka-2001 ≥110℃.

5. Ukucwebezela kanye nokuba yisicaba kobuso be-gel coat kuyadingeka ukuze kufinyelelwe ubuso be-A-level. Ngendiza evundlile, i-silhouette ingabonakala ngokucacile ngaphandle kokuguquka.

6. Izidingo zobulukhuni bomphezulu wejazi lejeli: inani elimaphakathi lobulukhuni bebhasi lamaphuzu ayi-10 okusabalala alinganiswa ngumzimba wesikhunta likhulu kune-35.

7. Isimo sobuso besikhunta asidingi amabhamuza ebusweni besikhunta, kungabi ngaphezu kwamabhamuza amathathu ngaphakathi kwe-1m2 yamabhamuza abonakalayo ku-gel coat kanye ne-mold laminate; akukho mabala asobala ebhulashi, imihuzuko kanye namabala okulungisa ebusweni besikhunta, futhi kungabi ngaphezu kwama-pinhole ama-5 ngaphakathi kwe-1m2 ebusweni. A, akunakuba khona into yokubeka izingqimba.

8. Uhlaka lwensimbi lwesikhunta lufanelekile, futhi kumele lube nesakhiwo sohlaka oluphelele. Ipulatifomu yokubamba kumele iqine futhi ingaguquki kalula; idivayisi ye-hydraulic ivula futhi ivale kahle nangokushelela, isivinini siyalungiseka, futhi kunikezwe iswishi yokuhamba, engahlangabezana nezikhathi zokuvula nokuvala ezingaphezu kwezikhathi eziyi-1000 ekusetshenzisweni okuvamile.

9. Isikhunta sakhiwe ngokwenqubo yokuhlanza umkhiqizo, ubukhulu bomzimba oyinhloko buyadingeka ukuze bufinyelele ku-15mm, kanti ubukhulu be-flange yesikhunta buyadingeka bube ngu-≥18mm.

10. Izikhonkwane zokubeka isikhunta ziyizikhonkwane zensimbi, kanti izikhonkwane nezingxenye ze-FRP kufanele zivalwe.

11. Umugqa wokusika wesikhunta uhlolwa ngokuqinile ngokwezinga lomkhiqizo.

12. Usayizi ofanayo wesikhunta udinga ukuba unembile, futhi iphutha elifanayo phakathi kwezingxenye ezifanayo kudingeka libe ngu-≤1.5mm.

13. Impilo evamile yenkonzo yesikhunta akufanele ibe ngaphansi kwamasethi angu-500 emikhiqizo.

14. Ukuthamba kwesikhunta kungu-±0.5mm ngemitha ngayinye eqondile, futhi akufanele kube nokungalingani.

15. Zonke izilinganiso zesikhunta ziqinisekisiwe ukuthi zinephutha elingu-±1mm, futhi akukho burr ebusweni be-laminate.

16. Ubuso besikhunta abuvunyelwe ukuba namaphutha afana nemigodi egobile, amaphethini e-orange peel, imihuzuko ye-sandpaper, imifantu yezinyawo zenkukhu, njll., futhi i-arc kufanele ibe noshintsho olubushelelezi.

17. Isikhunta siyasuswa ngemuva kokwelashwa ekushiseni okuphezulu okungu-80°C, bese sisuswa ngemva kwamahora angu-8.

18. Isikhunta asikwazi ukuguquguquka ngaphansi kwesimo se-exothermic peak esingu-90℃-120℃, futhi ubuso abukwazi ukubonakala bunamabala okushwabana, imifantu, kanye nokungalingani.

19. Kufanele kube nesikhala esingaphezu kuka-10mm phakathi kohlaka lwensimbi kanye nesikhunta, futhi inhlanganisela yemizimba emibili kufanele ifakwe i-cork noma amabhodi anezingqimba eziningi anobukhulu obufanayo.

20. Ilungu lesikhunta sokuhlukana alikwazi ukuhlukaniswa, ukwakheka kokubekwa kwesikhunta kunengqondo, isikhunta siyakhululwa, ukusebenza komkhiqizo kulula, futhi isikhunta kulula ukusikhulula.

21. Ingcindezi engemihle iyonke yesikhunta ingaphansi kuka-0.1, futhi ingcindezi igcinwa imizuzu emi-5.

Isikhathi sokuthunyelwe: Mashi-22-2022