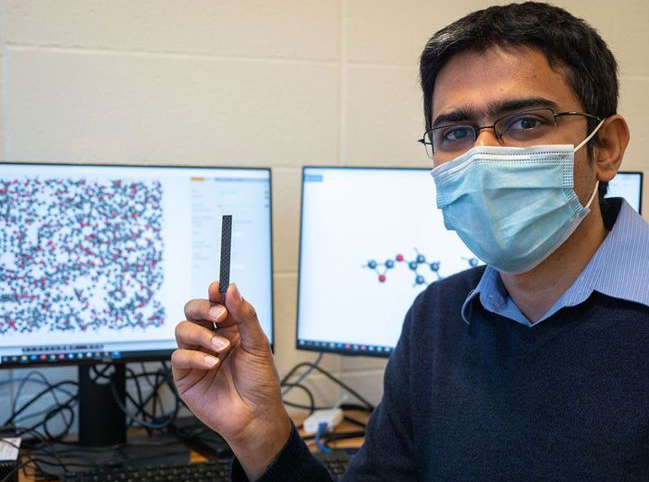

Ezinsukwini ezimbalwa ezedlule, uprofesa wase-University of Washington u-Aniruddh Vashisth washicilela iphepha ephephabhukwini eligunyaziwe lomhlaba wonke i-Carbon, ethi uphumelele ekwakheni uhlobo olusha lwezinto ezihlanganisiwe ze-carbon fiber. Ngokungafani ne-CFRP yendabuko, engenakulungiseka uma yonakele, izinto ezintsha zingalungiswa ngokuphindaphindiwe.

Ngenkathi igcina izakhiwo zemishini zezinto zendabuko, i-CFRP entsha yengeza inzuzo entsha, okungukuthi, ingalungiswa ngokuphindaphindiwe ngaphansi kwesenzo sokushisa. Ukushisa kungalungisa noma yimuphi umonakalo wokukhathala kwezinto, futhi kungasetshenziswa ukubola izinto lapho kudingeka ziphinde zisetshenziswe ekupheleni komjikelezo wenkonzo. Njengoba i-CFRP yendabuko ingenakuphinde isetshenziswe, kubalulekile ukuthuthukisa izinto ezintsha ezingaphinde zisetshenziswe noma zilungiswe kusetshenziswa amandla okushisa noma ukushisa kwemvamisa yomsakazo.

USolwazi Vashisth uthe umthombo wokushisa ungalibazisa unomphela inqubo yokuguga kwe-CFRP entsha. Empeleni, le nto kufanele ibizwe ngokuthi ama-Carbon Fiber Reinforced Vitrimers (vCFRP, ama-Carbon Fiber Reinforced Vitrimers). I-Glass polymer (ama-Vitrimers) uhlobo olusha lwezinto ze-polymer oluhlanganisa izinzuzo ze-thermoplastic kanye ne-thermosetting plastics ezasungulwa usosayensi waseFrance uSolwazi Ludwik Leibler ngo-2011. Izinto ze-Vitrimers zisebenzisa indlela yokushintshana kwezibopho ezinamandla, engenza ukushintshana kwezibopho zamakhemikhali okuguquguqukayo ngendlela enamandla lapho ishiswa, futhi ngesikhathi esifanayo igcine isakhiwo esixhumene sonke, ukuze ama-thermosetting polymers akwazi ukuziphilisa futhi acutshungulwe kabusha njengama-thermoplastic polymers.

Ngokuphambene nalokho, izinto ezivame ukubizwa ngokuthi izinto ezihlanganisiwe ze-carbon fiber yizinto ezihlanganisiwe ze-carbon fiber reinforced resin matrix (CFRP), ezingahlukaniswa zibe izinhlobo ezimbili: i-thermoset noma i-thermoplastic ngokwesakhiwo se-resin esihlukile. Izinto ezihlanganisiwe ze-thermosetting zivame ukuqukatha i-epoxy resin, izibopho zamakhemikhali lapho zingahlanganisa khona unomphela izinto zibe umzimba owodwa. Izinto ezihlanganisiwe ze-thermoplastic ziqukethe ama-resin e-thermoplastic athambile angancibilikiswa futhi acutshungulwe kabusha, kodwa lokhu kuzothinta ngokungenakugwenywa amandla nokuqina kwezinto.

Izibopho zamakhemikhali ku-vCFRP zingaxhunywa, zinqanyulwe, futhi zixhunywe kabusha ukuze kutholakale "indawo ephakathi" phakathi kwezinto ze-thermoset nezinto ze-thermoplastic. Abacwaningi bephrojekthi bakholelwa ukuthi ama-Vitrimers angaba indawo yama-resin e-thermosetting futhi agweme ukuqongelela kwezinto ezihlanganisiwe ze-thermosetting ezindaweni zokulahla udoti. Abacwaningi bakholelwa ukuthi i-vCFRP izoba ushintsho olukhulu kusuka ezintweni zendabuko kuya ezintweni ezishintshashintshayo, futhi izoba nochungechunge lwemiphumela maqondana nezindleko zomjikelezo wokuphila ogcwele, ukuthembeka, ukuphepha, kanye nokugcinwa.

Njengamanje, ama-blade e-wind turbine angenye yezindawo lapho ukusetshenziswa kwe-CFRP kukhulu khona, futhi ukubuyiswa kwama-blade bekulokhu kuyinkinga kule nsimu. Ngemva kokuphela kwesikhathi senkonzo, izinkulungwane zama-blade asebethathe umhlalaphansi zalahlwa endaweni yokulahla udoti ngendlela yokulahla udoti, okwabangela umthelela omkhulu emvelweni.

Uma i-vCFRP ingasetshenziswa ekukhiqizeni ama-blade, ingase isetshenziswe kabusha futhi isetshenziswe kabusha ngokushisa okulula. Ngisho noma i-blade ephathwayo ingenakulungiseka futhi isetshenziswe kabusha, okungenani ingabola ngokushisa. Izinto ezintsha ziguqula umjikelezo wokuphila oqondile wama-thermoset composites ube umjikelezo wokuphila ojikelezayo, okuzoba yisinyathelo esikhulu esiya entuthukweni esimeme.

Uma i-vCFRP ingasetshenziswa ekukhiqizeni ama-blade, ingase isetshenziswe kabusha futhi isetshenziswe kabusha ngokushisa okulula. Ngisho noma i-blade ephathwayo ingenakulungiseka futhi isetshenziswe kabusha, okungenani ingabola ngokushisa. Izinto ezintsha ziguqula umjikelezo wokuphila oqondile wama-thermoset composites ube umjikelezo wokuphila ojikelezayo, okuzoba yisinyathelo esikhulu esiya entuthukweni esimeme.

Isikhathi sokuthunyelwe: Novemba-09-2021