Ipulasitiki eqiniswe nge-fiberglass (i-FRP)Izikebhe zinezinzuzo zesisindo esincane, amandla aphezulu, ukumelana nokugqwala, ukulwa nokuguga, njll. Zisetshenziswa kabanzi emikhakheni yokuhamba, ukubuka izindawo, imisebenzi yebhizinisi njalo njalo. Inqubo yokukhiqiza ayibandakanyi nje isayensi yezinto ezibonakalayo, kodwa futhi nokulawula inqubo okuhle ukuqinisekisa ikhwalithi nokusebenza komkhiqizo wokugcina.

Inqubo yokukhiqiza izikebhe zepulasitiki eziqiniswe nge-fiberglass

(1) Ukuguqulwa kwesikhunta:Izikhunta ezisetshenziswa kulo msebenzi zonke zinikezwa ngaphandle, futhi ngezinye izikhathi izikhunta zidinga ukuguqulwa okulula.

(2) Ukuhlanza isikhunta:Hlanza isikali se-wax bese ususa uthuli ebusweni besikhunta. Hlanza i-gauze ukuze uhlanze zonke izingxenye zobuso besikhunta.

(3) I-ejenti yokukhulula edlalayo:Hlikihla ngokulinganayo into yokukhulula ebusweni besikhunta ukuze wakhe ungqimba oluncane lwesembozo esibushelelezi, linda imizuzu eyi-15 ukuze uthole ungqimba olulandelayo lwesembozo, isikhunta ngasinye kufanele siphindwe izikhathi eziyi-7 kuya kweziyi-8.

(4) ijazi lejeli lokupenda:upende wejeli esikhumbeni, ijeli yejazi izinto zokusetshenziswa zejeli yejeli yeresin, ukusetshenziswa kwamabhulashi okwenziwa, ama-bristle rollers ukupenda ijeli yejazi, upende olukhanyayo kuqala bese kuba upende ojulile ofanayo.

(5) Ukusika:sebenzisa isikele noma i-blade ukusika indwangu ye-fiberglass ibe nobude obufanele.

(6) Ukuxuba nokuhlanganisa:sebenzisa izinkomishi zokulinganisa ukuze ungeze i-ejenti yokwelapha ku-resin ye-polyester engagcwele bese uxuba kahle, ukuze i-resin iqine ibe yinto eqinile phakathi nesikhathi esithile, inqubo yokwelapha ekamelweni lokushisa ngaphandle kokushisa.

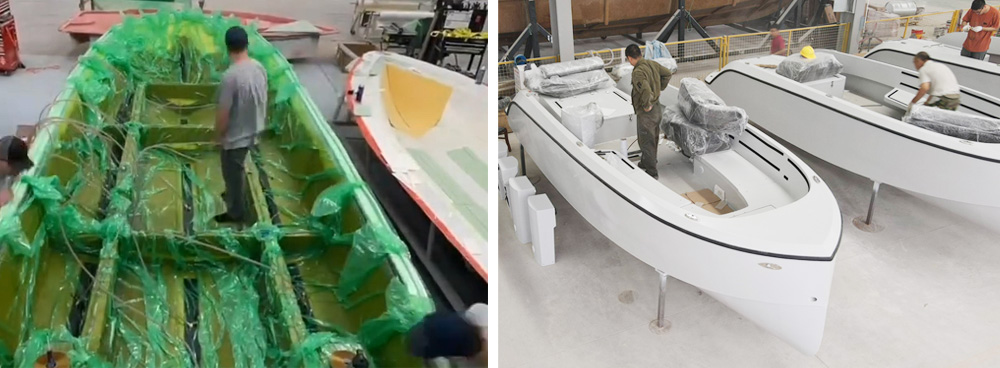

(7) Ukuqongelela kwezingqimba:ukuqongelela kwezingqimba zenqubo yephrojekthi yokunamathisela ngesandla kanye ne-vacuum ngezindlela ezimbili.

Ukunamathisela ngesandla:ngemva kokuba ijazi lejeli liqina ngezinga elithile, i-resin izoxutshwa futhi ibhulashwe engqimbeni yejazi lejeli, bese kuba ukunqunywa kwangaphambiliniindwangu ye-fiberglassizosakazwa phezu kwengqimba ye-resin, bese i-pressure roller icindezela indwangu ye-fiberglass ukuze ihlanganiswe ngokulinganayo ne-resin bese ikhipha amabhamuza omoya. Ngemva kokuba ungqimba lokuqala seluqediwe futhi lulungisiwe, hlikihla i-resin bese ubeka indwangu ye-fiberglass futhi, njalo njalo kuze kube yilapho inani elithile lezingqimba lizosebenza.

Umshini wokuhlanza:beka inani elibekiwe lezingqimba zendwangu ye-fiberglass esibonakalayo sesikhunta, bese ubeka ungqimba lwendwangu yendwangu yokufakwa, ishubhu lokufakwa, unamathisele i-tape yokuvala, bese ubeka ulwelwesi lwesikhwama sokuhlanza, faka i-valve yokuhlanza, isixhumi esisheshayo, ishubhu lokuhlanza, vula iphampu yokuhlanza ukuze usebenzise ingcindezi engemihle izokhishwa emoyeni, futhi ekugcineni ukusetshenziswa kwengcindezi engemihle kuzoba sezingeni lokushisa legumbi kuzosetshenziswa ukufaka i-resin esikhwameni sokuhlanza ngaphakathi kwezimo zemvelo (izinga lokushisa legumbi) ukwelapha, ukwelapha, ukususwa kwesikhwama sokuhlanza ngemuva kokukhululwa kwesikhunta. Ngemuva kokupholisa, isikhwama sokuhlanza siyasuswa futhi sisuswe.

Enkambisweni yokubeka ibhulashi, i-fiberglass kanye ne-resin kusetshenziswa ibhulashi eligoqekayo, kudingeka kuhlanzwe ngesikhathi, kuhlanzwe kusetshenziswa i-acetone.

(8) ukubeka ukuqinisa:ngokwezidingo zokuqinisa, izinto eziyinhloko zisikwa zibe usayizi nesimo esidingekayo, bese kuba inqubo yokuqongelela, lapho ungqimba lokuqongelela lwe-FRP lufinyelela ubukhulu bezidingo zomklamo, kuyilaphoI-resin ye-FRPisalokhu i-gelling, ifakwa ngokushesha ezintweni eziyinhloko, futhi ngokushesha ngangokunokwenzeka ngesisindo esifanele sokucindezela kuzoba yizinto eziyinhloko zefulethi engqimbeni ye-FRP, ukuze kube ukupholisa kwe-FRP, susa isisindo, bese uqoqa ungqimba lwendwangu ye-fiberglass.

(9) ukunamathelisa izimbambo:I-FRP shell ihlukaniswe kakhulu izingxenye eziphezulu nezingezansi, kudingeka isebenzise i-resin kanyeindwangu ye-fiberglassengxenyeni engezansi yesikhunta esakhiwe izingxenye zembambo ezinamathele esiqwini, ukuze kube lula ukulungisa nokufaka ingxenye engenhla yesikhumba. Isimiso sokunamathelisa imbambo sifana nese-ply.

(10) ukususwa kwesakhiwo:i-laminate ingasuswa ngemva kwesikhathi esithile sokuqiniswa, futhi imikhiqizo ikhishwa esikhumbeni kusukela emaphethelweni womabili esikhumbeni.

(11) Ukugcinwa kwesikhunta:gcina isikhunta usuku olulodwa. Sebenzisa ithawula elihlanzekile ukuze usule into ekhipha ukungcola, ugcobe indwangu izikhathi ezimbili.

(12) Ukuhlanganisa:Hlanganisa amagobolondo aphezulu nawaphansi asuliwe futhi ahluliwe, sebenzisa inhlaka yokwakheka ukuze unamathisele ndawonye amagobolondo aphezulu nawaphansi bese uhlanganisa isikhunta.

(13) Ukusika, ukuhlikihla kanye nokubhoboza:Amagobolondo kudingeka asikwe, ahlanzwe kancane futhi abholwe ukuze kuhlanganiswe ihadiwe kanye nezinto zokufakelwa zensimbi engagqwali kamuva.

(14) Ukuhlanganiswa komkhiqizo:i-bock, i-hinge, imigodi yokufaka intambo, i-drain, izikulufu nezinye izinto zehadiwe kanye ne-backrest, isibambo kanye nezinye izinto zokufaka insimbi engagqwali ngokwezidingo zamakhasimende kusetshenziswa izikulufo ezifakwe esihlahleni.

(15) Ifektri:isikebhe esihlanganisiwe sizophuma efektri ngemuva kokudlula ukuhlolwa.

Isikhathi sokuthunyelwe: Okthoba-08-2024