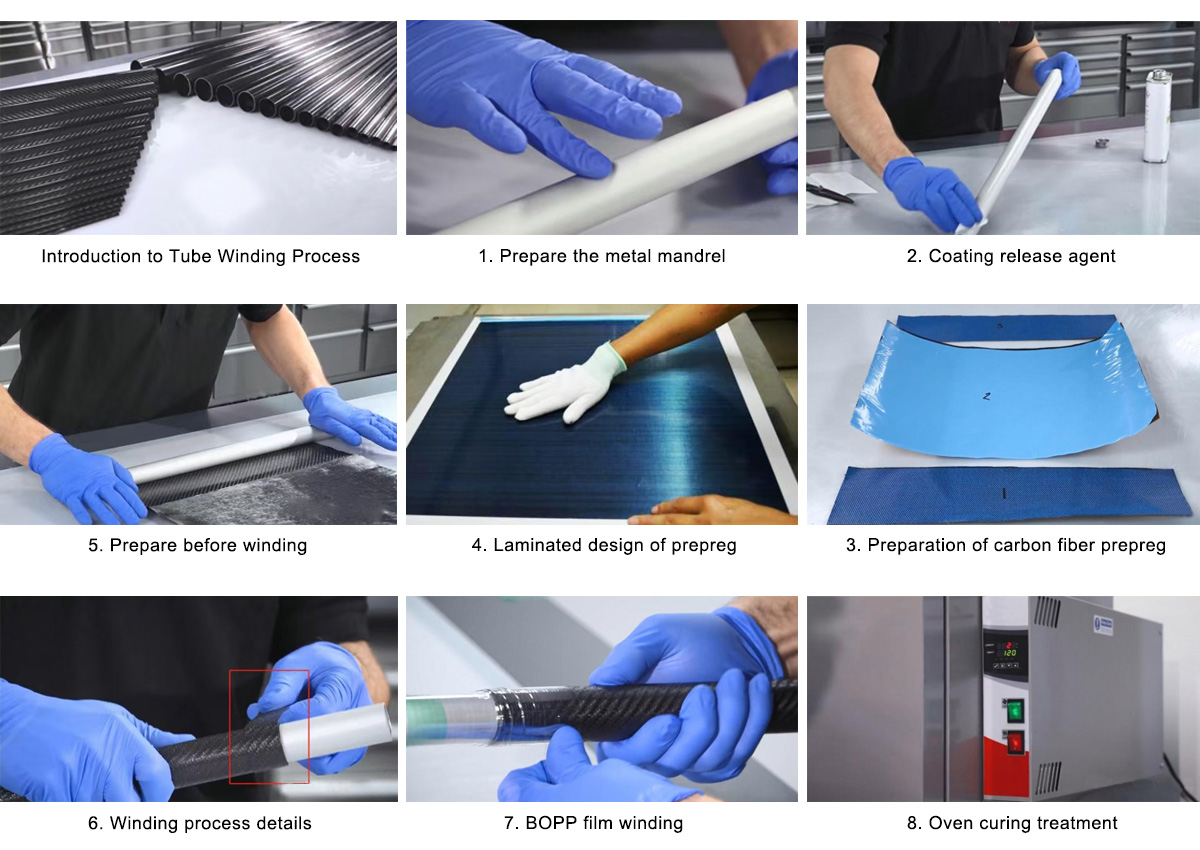

1. Isingeniso senqubo yokubopha amapayipi

Ngalesi sifundo, uzofunda ukuthi ungayisebenzisa kanjani inqubo yokugoqa ishubhu ukwakha izakhiwo zamashubhu usebenzisa ama-prepreg e-carbon fiber emshinini wokugoqa ishubhu, ngaleyo ndlela ukhiqize amandla aphezulu.amashubhu e-carbon fiberLe nqubo ivame ukusetshenziswa abakhiqizi bezinto ezihlanganisiwe.

Uma ufisa ukukhiqiza amashubhu anezinhlangothi ezifanayo noma i-taper eqhubekayo, inqubo yokugoqa amashubhu iyindlela efanelekile. Okudingayo nje i-mandrel yensimbi enobukhulu obufanele kanye ne-oven yokwenza amashubhu e-carbon fiber enziwe ngokwezifiso afanela izidingo zakho ezithile.

Kumashubhu e-carbon fiber anesimo esiyinkimbinkimbi, njengezibambo noma izakhiwo zohlaka oluyinkimbinkimbi kakhulu njengezimfoloko zokumiswa noma ozimele bamabhayisikili, ubuchwepheshe be-split-mold buyindlela ekhethwayo. Manje sizobonisa indlela yokusebenzisa ubuchwepheshe be-split-mold ukukhiqiza la mashubhu e-carbon fiber ayinkimbinkimbi.

2. Ukucutshungulwa Nokulungiswa Kwe-Metal Mandrels

- Ukubaluleka Kwama-Metal Mandrels

Ngaphambi kokuqala inqubo yokugoqa ipayipi, isinyathelo sokuqala ukulungiselela ama-mandrel ensimbi. Ama-mandrel ensimbi kumele afane nobubanzi bangaphakathi bamapayipi, futhi ukushelela kwawo ebusweni kanye nokwelashwa okufanele kusengaphambili kubalulekile. Ngaphezu kwalokho, ama-mandrel ensimbi kumele aphathwe kahle kusengaphambili, njengokuhlanza nokusebenzisa i-ejenti yokukhulula, ukuze kube lula inqubo elandelayo yokudiliza.

Ngesikhathi senqubo yokugoqa ithubhu, i-mandrel yensimbi idlala indima ebalulekile njengoba kumele isekeleukulungiswa kwe-carbon fiberukuqinisekisa ukugoba okubushelelezi. Ngakho-ke, ukulungiselela usayizi ofanele we-mandrel yensimbi kusengaphambili kubalulekile. Njengoba i-carbon fiber izogoqwa izungeze ubuso bangaphandle be-mandrel, ububanzi bangaphandle be-mandrel kumele bufane nobubanzi bangaphakathi beshubhu le-carbon fiber elizokhiqizwa.

- I-ejenti yokukhulula efaka isicelo

Izinto zokukhulula zinciphisa ukungqubuzana futhi ziqinisekise ukuthi ziguquguquka kahle; kumele zisetshenziswe ngokulinganayo ebusweni be-mandrel. Ngemva kokuthi i-mandrel yensimbi isilungisiwe, isinyathelo esilandelayo ukufaka i-ejenti yokukhulula. Izinto zokukhulula ezisetshenziswa kakhulu zifaka uwoyela we-silicone ne-paraffin, okunciphisa ngempumelelo ukungqubuzana phakathi kwe-carbon fiber ne-mandrel yensimbi.

Ku-mandrel yensimbi elungisiwe, kumele siqinisekise ukuthi ihlanzekile kahle futhi indawo ibushelelezi ngangokunokwenzeka ukuze kube lula ukususa umkhiqizo ngokushelela. Ngemva kwalokho, into yokukhulula kufanele isetshenziswe ngokulinganayo ebusweni be-mandrel.

3. Ukulungiswa kwe-carbon fiber prepreg

- Izinhlobo nezinzuzo ze-prepreg

Ama-prepreg e-carbon fiber kuphela ahlangabezana nezidingo eziphezulu zokunemba kokugoqa kanye nokulula kokuphatha. Nakuba ezinye izinhlobo zezinto zokuqinisa, njengezindwangu ezomile ezifakwe i-epoxy, zingasetshenziswa ngokombono enkambisweni yokugoqa, empeleni, ama-prepreg e-carbon fiber kuphela angahlangabezana nezidingo eziphezulu zokunemba kanye nokulula kokuphatha kule nqubo.

Kulesi sifundo, sisebenzisa indlela ethile yokubeka izingqimba ukuze sithuthukise ukusebenza kwepayipi.

- Umklamo Wokulayisha Ngaphambi Kokukhulelwa

Ingqimba ye-prepreg elukiwe ibekwa ohlangothini lwangaphakathi lwethubhu, ilandelwe yizingqimba eziningana ze-prepreg eqondiswe eceleni, bese kuthi ekugcineni kube nenye ingqimba ye-prepreg elukiwe ohlangothini lwangaphandle lwethubhu. Lo mklamo we-layup usebenzisa ngokugcwele izinzuzo zokuqondiswa kwefayibha ze-prepreg elukiwe kuma-axes angu-0° no-90°, okuthuthukisa kakhulu ukusebenza kwethubhu. Iningi lama-prepreg alukiwe abekwe ku-axis engu-0° anikeza ukuqina okuhle kakhulu kwephayiphi.

4. Ukugeleza kwenqubo yokugoqa ipayipi

- Ukulungiselela ukugoqa ngaphambi kokubopha

Ngemva kokuqeda umklamo wokubeka i-prepreg, inqubo iqhubekela enkambisweni yokugoqa amapayipi. Ukucubungula i-prepreg kuhilela ukususa ifilimu ye-PE kanye nephepha lokukhulula, kanye nokugcina izindawo ezifanele zokugoqana. Lesi sinyathelo sibalulekile ekuqinisekiseni ukuqhubeka okubushelelezi kwezinqubo zokugoqa ezilandelayo.

- Imininingwane yenqubo yokugoqa

Ngesikhathi senqubo yokugoqa, kubalulekile ukuqinisekisa ukugoqa okubushelelezi kwama-prepregs, lapho i-metal core shaft ibekwa kancane kancane futhi iphoqelekile isetshenziswa ngokulinganayo. I-metal core shaft kufanele ibekwe kancane kancane emaphethelweni engqimba yokuqala yama-prepregs, ukuqinisekisa ukusetshenziswa kwamandla ngokulinganayo.

Ngesikhathi sokusonga, ama-prepreg engeziwe angalinyazwa emaphethelweni ukuze kube lula ukususwa komkhiqizo ngesikhathi sokususa.

- Ukugoqwa Kwefilimu le-BOPP

Ngaphezu kwe-prepreg, ifilimu ye-BOPP ingasetshenziswa futhi ekusongeni. Ifilimu ye-BOPP yandisa ingcindezi yokuhlanganisa, ivikela, futhi ivale i-prepreg. Uma usebenzisa ifilimu yokusonga ye-BOPP, kubalulekile ukuqinisekisa ukufana okwanele phakathi kwamatheyipu.

5. Inqubo Yokwelapha Ihhavini

- Ukushisa Nokushisa Isikhathi

Ngemva kokusonga ngokuqinile izinto eziqiniswe nge-prepreg carbon fiber, zithunyelwa kuhhavini ukuze ziyoqiniswa. Ukulawula izinga lokushisa kubalulekile ngesikhathi sokuqina kuhhavini, njengoba izinto ezahlukene zokulungiselela zinezimo ezahlukene zokuqina. Lesi sinyathelo sibalulekile ekuqinisekiseni ukuzinza kwezinto nokuthuthukisa ukusebenza.

Ngokusebenzisa indawo yokushisa ephezulu kuhhavini,i-carbon fiberkanye ne-resin matrix zisabela ngokugcwele, zakha into eqinile ehlanganisiwe.

6. Ukususwa Nokucubungula

Ngemva kokususa ifilimu yokusonga ye-BOPP, umkhiqizo osuqediwe ungasuswa. Ifilimu ye-BOPP ingasuswa ngemva kokuphola. Uma kudingeka, ukubukeka kungathuthukiswa ngokuphola nokupenda. Ukuze kuthuthukiswe ubuhle, kungenziwa izinqubo ezengeziwe zokuqeda njengokuphola nokupenda.

Isikhathi sokuthunyelwe: Agasti-11-2025