Izici Zomkhiqizo

Amandla aphezulu kanye nokusebenza kahle okuphezulu, ukumelana nokugqwala, ukumelana nokushaqeka, ukumelana nokushayisana, ukwakhiwa okulula, ukuqina okuhle, njll.

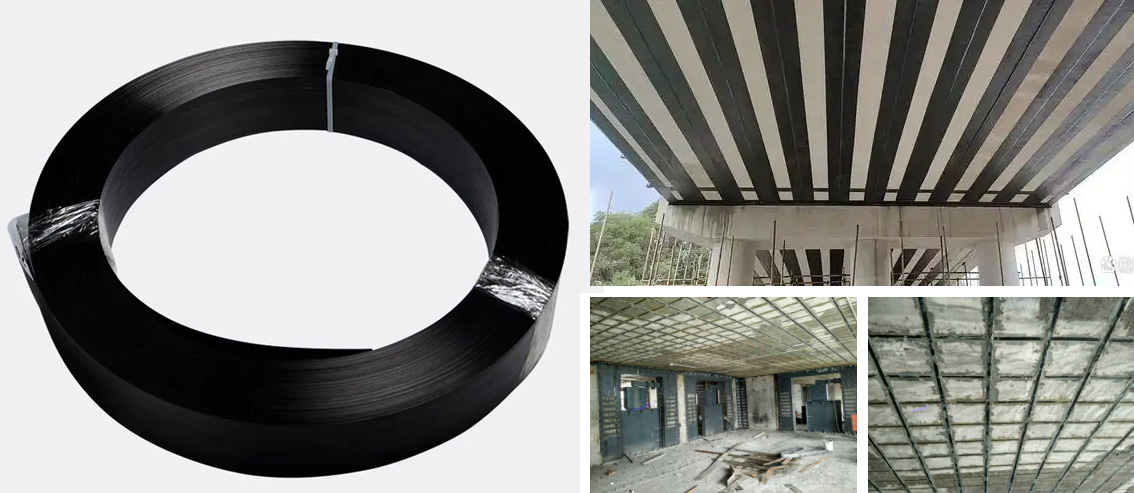

Ububanzi besicelo

Ukugoba izingodo zekhonkrithi, ukuqinisa ukucheba, ama-slab phansi ekhonkrithi, ukuqinisa i-bridge deck, ukhonkrithi, izindonga zokwakha ngezitini, ukuqinisa udonga lwesikelo, imigudu, amachibi okubhukuda nokunye ukuqinisa ukuqinisa.

Isitoreji kanye nokuthuthwa

Kufanele igcinwe endaweni eyomile, epholile futhi enomoya opholile, ukugwema ukuchayeka emvuleni noma elangeni.

Inqubo yokuthutha nokugcina akufanele ikhishwe, ukuze kugwenywe umonakaloi-carbon fiber.

Imiyalelo yokwakha yokuqinisa ipuleti le-Vibranium

1. Ukwelashwa kwe-substrate yekhonkrithi

(1) Thola bese ubeka umugqa ngokwemidwebo yomklamo engxenyeni yokunamathisela eklanyelwe.

(2) Ubuso bekhonkrithi kufanele buqhekezwe bususwe kungqimba olumhlophe, uwoyela, ukungcola, njll., bese usebenzisa i-engela grinder ukuze ugaye ungqimba olungaphezulu oluyi-1 ~ 2mm ubukhulu bese uluhlanza nge-blower ukuze uveze ubuso obuhlanzekile, obuyisicaba, obuqinile ngokwesakhiwo, uma kukhona imifantu kukhonkrithi eqinisiwe, kufanele kuqala kuye ngobukhulu bemifantu ukuze ukhethe ukugcwalisa i-glue noma i-grouting glue grouting bese kuba ukuqinisa.

2. Ukwelashwa kokulinganisa

Uma kukhona amaphutha, imigodi kanye nokhalo oluphezulu ezinhlanganisweni zethempulethi ebusweni obunamathiselwe, sebenzisa ingcina yokulinganisa ukuze uklwebhe futhi ugcwalise ukulungiswa ukuqinisekisa ukuthi akukho mehluko ocacile wokuphakama ezinhlanganisweni, amaphutha kanye nemigodi kubushelelezi futhi kubushelelezi. Ukulungisa iglue yokulinganisa bese unamathisela ibhodi le-carbon fiber.

3. Namathiselaibhodi le-carbon fiber

(1) Sika ibhodi le-carbon fiber ngokuya ngosayizi odingekayo ngomklamo.

(2) Ingxenye ye-A kanye nengxenye ye-B ngokwesilinganiso sokucushwa okungu-2:1, ukusetshenziswa kokuxuba, isikhathi sokuxuba cishe imizuzu emi-2 ~ 3, ukuxuba ngokulinganayo, nokuvimbela ukungcola kothuli okuxubile. Ingxenye ye-A ehlanganisiwe akufanele ibe yiningi kakhulu, ukuqinisekisa ukuthi ukucushwa kokuqediwe kungakapheli imizuzu engama-30 (25 ℃).

(3) Ubuso bebhodi le-carbon fiber kufanele busulwe kahle, kusetshenziswa i-plastic scraper kuzogqokwa ingcina yesakhiwo ebhodini le-carbon fiber, ukujiya kwengcina yesakhiwo okungu-1-3mm (indawo ephakathi yebhodi le-carbon fiber engu-3mm), kwakuphakathi kwezinhlangothi ezijiyile zobukhulu obuncane, ukujiya okumaphakathi okungu-2mm.

(4) Beka ibhodi le-carbon fiber esisekelweni sokuqinisa ukhonkolo, nge-roller yerabha efaka ingcindezi eyanele ngokulinganayo, ukuze inhlaka yesakhiwo evela ezinhlangothini zombili zokuchichima, ukuqinisekisa ukuthi akukho mgodi, ukuqinisekisa ukuthi ibhodi le-carbon fiber kanye nesisekelo sekhonkolo zinobukhulu obungu-2mm obuqondile benhlaka.

(5) Susa izinto ezinamathelayo ezidlulele ezungeze umngcele, sebenzisa ibha lokhuni noma uhlaka lwensimbi ukusekela nokulungisa ibhodi le-carbon fiber, ufake ingcindezi efanele, bese ususa ukwesekwa ngemva kokuba ingcina yesakhiwo isilungisiwe. Uma amabhodi amaningi e-carbon fiber enamathiselwe ndawonye, igebe phakathi kwamabhodi amabili alingaphansi kuka-5mm.

(6) unamathisele izendlalelo ezimbili zebhodi le-carbon fiber kufanele zibe unamathisele oqhubekayo, ungqimba olungezansi lwebhodi le-carbon fiber kuzo zombili izinhlangothi kufanele lusulwe kahle, njengoba lungenakunamathiselwa ngokushesha bese luvula unamathisele ngaphambi kokuba ungqimba olungezansi lwebhodi le-carbon fiber kufanele luphinde lwenziwe umsebenzi wokuhlanza. Uma izingxenye zokuqinisa zidinga ukwenza ukuvikelwa kokugqoka, ungaxubha ungqimba lokuvikela ngemuva kokulungisa i-resin.

Izinyathelo Zokuqapha Ukwakha

1. Uma izinga lokushisa lingaphansi kuka-5℃, umswakama ohlobene RH>85%, okuqukethwe kwamanzi ebusweni bekhonkrithi kungaphezu kuka-4%, futhi kungenzeka ukuthi kube nokujiya, ukwakhiwa akufanele kwenziwe ngaphandle kwezinyathelo ezisebenzayo. Uma izimo zokwakha zingafinyelelwa, kuyadingeka ukusebenzisa indlela yokushisa kwendawo yendawo yokusebenza ukuze kufezwe izinga lokushisa elihlobene elidingekayo, umswakama kanye nokuqukethwe komswakama kanye nezinye izimo ngaphambi kokwakhiwa, izinga lokushisa lokwakha elingu-5℃ -35℃ liyafaneleka.

2. Ngenxa yokuthi i-carbon fiber iyisiphehli sikagesi esihle, kufanele igcinwe kude nomthombo wamandla.

3. I-resin yokwakha kufanele igcinwe kude nomlilo ovulekile kanye nokukhanya kwelanga okuqondile, futhi i-resin engasetshenziswanga kufanele ivalwe.

4. Abasebenzi bokwakha nabahlola kufanele bagqoke izingubo zokuzivikela, izigqoko zokuphepha, imaski, amagilavu, nezibuko zokuzivikela.

5. Uma i-resin inamathela esikhumbeni, kufanele ihlanzwe ngokushesha ngensipho namanzi, ifafazwe emehlweni ngamanzi kanye nokunakekelwa kwezokwelapha ngesikhathi esifanele. 6, ukwakhiwa ngakunye kuqediwe, ukulondolozwa kwemvelo kungakapheli amahora angama-24 ukuqinisekisa ukuthi akukho mthelela wangaphandle oqinile kanye nokunye ukuphazamiseka.

7. Inqubo ngayinye yenqubo futhi ngemva kokuphothulwa, kufanele ithathe izinyathelo ezifanele ukuqinisekisa ukuthi akukho ukungcola noma ukungena kwamanzi emvula. 8. Ukumiswa kwendawo yokwakha yento yokunamathisela isakhiwo kumele kugcinwe kungeniswe umoya kahle.

9. ngenxa yokugoqwa kweibhodi le-carbon fiberinokucindezeleka okukhulu, lapho kukhishwa ibhodi le-carbon fiber kudingeka abantu abangu-2-3 ngokukhululwa kwe-roll, ukuvimbela ibhodi le-carbon fiber ukuthi liqhume ukulimala okuvulekile.

10. Inqubo yokuphatha ipuleti le-carbon fiber kudingeka ibe lula, ivinjelwe ezintweni eziqinile futhi umuntu ayinyathele.

11. Ukwakhiwa kuhlangabezane nokwehla okungazelelwe kwezinga lokushisa, i-viscosity yesakhiwo esinamathelayo izobonakala inkulu, ungathatha izinyathelo zokushisa, njengezibani ze-iodine ze-tungsten, izitofu zikagesi noma amabhavu amanzi kanye nezinye izindlela zokwandisa izinga lokushisa le-glue ngaphambi kokusebenzisa ukuze kufudunyezwe kusengaphambili ku-20 ℃ -40 ℃.

Isikhathi sokuthunyelwe: Ephreli-27-2025