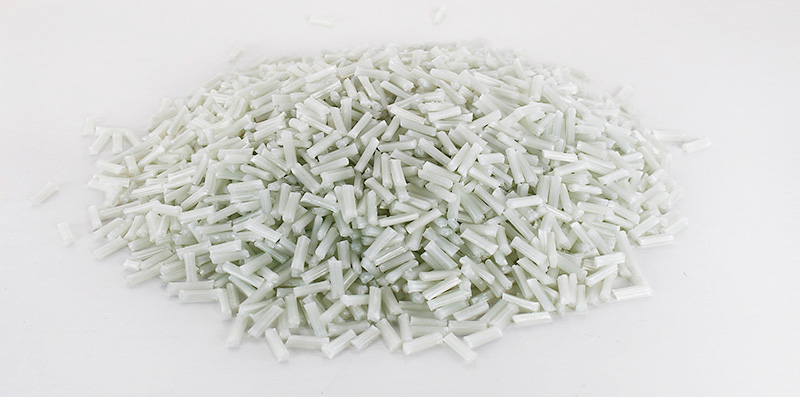

Ukulungiselela Izinto Ezingavuthiwe

Ngaphambi kokukhiqiza isikhathi esideizinhlanganisela ze-polypropylene eziqiniswe nge-fiberglass, kudingeka ukulungiswa okwanele kwezinto zokusetshenziswa. Izinto zokusetshenziswa eziyinhloko zifaka i-polypropylene (PP) resin, i-long fiberglass (LGF), izithasiselo nokunye. I-polypropylene resin iyinto ye-matrix, imicu yengilazi ende njengezinto zokuqinisa, izithasiselo ezifaka phakathi ama-plasticizer, ama-stabilizer, amafutha okugcoba, njll., asetshenziselwa ukuthuthukisa izakhiwo zokucubungula kanye nezakhiwo zemishini zezinto.

Ukungena kwe-Fiberglass

Esigabeni sokungena kwefayibha yengilazi, imicu yengilazi ende ifakwa ku-polypropylene resin. Lesi sinyathelo sivame ukusebenzisa indlela yokuxuba ngaphambi kokufakwa noma ngokuqondile, ukuze ifayibha yengilazi ifakwe ngokuphelele yi-resin, okubeka isisekelo sokulungiswa okulandelayo kwezinto ezihlanganisiwe.

Ukuhlakazeka kwe-Fiberglass

Esigabeni sokusabalala kwe-fiberglass, imicu yengilazi ende efakwe ngaphakathi ixutshwa kakhulu ne-i-polypropylene resinendaweni yokuxuba ukuqinisekisa ukuthi imicu ihlakazeke ngokulinganayo ku-resin. Lesi sinyathelo sibalulekile ekusebenzeni kwezinto ezihlanganisiwe, futhi kuyadingeka ukuqinisekisa ukuthi i-fiber ihlakazeke kahle ku-resin.

Ukubumba Ngomjovo

Esigabeni sokubumba ngomjovo, izinto ezihlanganisiwe ezixutshwe kahle zibunjwa ngomshini wokubumba ngomjovo. Ngesikhathi senqubo yokubumba ngomjovo, izinto ziyashiswa bese zifakwa esikhumbeni, bese zipholiswa ukuze kwakhiwe umkhiqizo ohlanganisiwe onesimo nosayizi othize.

Ukwelashwa Kokushisa

Ukwelashwa ngokushisa kuyingxenye ebalulekile yenqubo yokukhiqiza isikhathi esideizinhlanganisela ze-polypropylene eziqiniswe nge-fiberglassNgokwelashwa ngokushisa, izakhiwo zemishini kanye nokuqina kwenhlanganisela kungathuthukiswa kakhulu. Ukwelashwa ngokushisa ngokuvamile kuhilela izinyathelo zokushisa, zokubamba kanye nokupholisa ukuze kufezwe ukusebenza okuhle kakhulu kwenhlanganisela.

Ukupholisa nokulinganisa

Esigabeni sokupholisa nokubumba, imikhiqizo ehlanganisiwe ephathwa ngokushisa ipholiswa yimishini yokupholisa, ukuze imikhiqizo ibumbeke. Lesi sinyathelo sibalulekile ukuqinisekisa ukuzinza kobukhulu kanye nekhwalithi yobuso bomkhiqizo.

Ngemva kokucutshungulwa

Ukucubungula ngemuva kokucubungula kuwukucubungula okuqhubekayo kwemikhiqizo ehlanganisiwe epholile nebunjwe ngendlela efanayo, njengokusika, ukugaya, njll., ukuze kususwe ama-burrs kanye nokungapheleli ebusweni bemikhiqizo, kanye nokuthuthukisa ukubukeka kanye nokunemba kwemikhiqizo.

Ukuhlolwa Kwekhwalithi

Okokugcina, izinhlanganisela ze-polypropylene eziqiniswe ngefayibha yengilazi ende ziyahlolwa ukuze kutholakale ikhwalithi. Ukuhlolwa kwekhwalithi kuhlanganisa ukuhlolwa kokubukeka, ukulinganiswa kosayizi, ukuhlolwa kwempahla yemishini, njll., ukuqinisekisa ukuthi imikhiqizo ihlangabezana nezidingo zomklamo kanye nezindinganiso ezifanele. Ukuhlolwa kwekhwalithi kungaqinisekisa ukuthi imikhiqizo ehlanganisiwe isebenza kahle futhi izinzile.

Inqubo yokukhiqiza yesikhathi esidei-fiberglassIzinhlanganisela ze-polypropylene eziqinisiwe zifaka phakathi izinyathelo zokulungiselela izinto zokusetshenziswa, ukungena kwe-fiberglass, ukuhlakazwa kwe-fiberglass, ukubumba ngemijovo, ukwelashwa kokushisa, ukupholisa nokubumba, ukuhlolwa komkhiqizo ngemuva kokwelashwa kanye nokuhlolwa kwekhwalithi. Ngokulawula okuqinile kanye nokuqaliswa kwale nqubo, imikhiqizo ye-polypropylene eqinisiwe ye-fiberglass ende esezingeni eliphezulu ingakhiqizwa.

Isikhathi sokuthunyelwe: Okthoba-14-2024