Eminyakeni emibili edlule, eqhutshwa ukuvela kobuchwepheshe bezinto zokuvikela ukushisa ezibalekayo zamabhethri amasha wamandla, amakhasimende afuna kakhulu ukusebenza okuthuthukisiwe kokuvikela ukushisa kanye nokumelana nokushisa okufana nobumba—isici esibalulekile sokumelana nomlilo.

Isibonelo, ezinye izinhlelo zokusebenza zidinga amazinga okushisa okushisa kwelangabi angaphambili angu-1200°C kuyilapho kugcinwa amazinga okushisa angemuva angaphansi kuka-300°C. Ezintweni zezindiza, ukukhishwa kwelangabi acetylene angaphambili ku-3000°C kudinga amazinga okushisa angemuva angaphansi kuka-150°C. Inselele kakhulu isidingo esikhulu sokusebenza kokucindezela ku-silicone foam eyenziwe nge-ceramic, edinga kokubili isethi yokucindezela okuphansi kanye nokugcinwa okuhle kokushisa kokushisa emazingeni okushisa aphezulu. Lezi zinto zizonke ziveza izidingo ezintsha zokushisa kobuchwepheshe be-ceramicization.

Izidingo zokusebenza ezithile (ngokwereferensi kuphela):

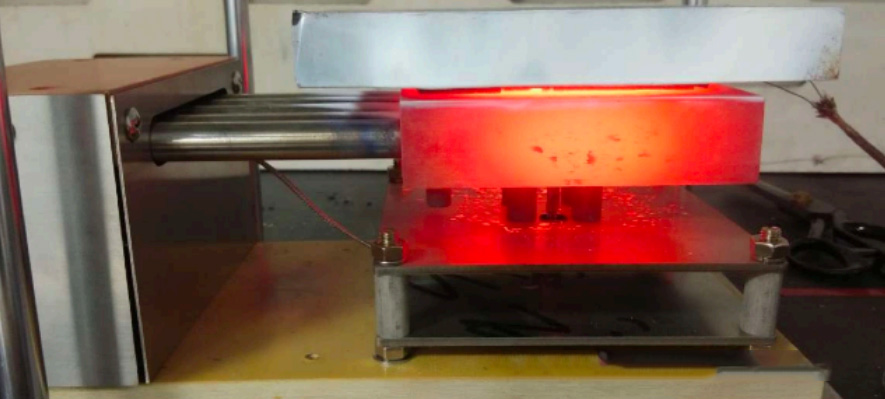

Shisisa isampula epulatifomu yokushisa njengoba kuboniswe ngezansi. Gcina indawo eshisayo ku-600 ± 25 °C imizuzu eyi-10. Faka ukucindezeleka okungu-0.8±0.05 MPa ekushiseni kokuhlola, uqinisekise ukuthi izinga lokushisa lobuso bangemuva lihlala lingaphansi kuka-200°C.

Namuhla, sifingqa la maphuzu ukuze uwabhekisele kuwe.

1. I-Silicate Yokwenziwa Ye-Calcium – I-Thermal Insulation White Filler

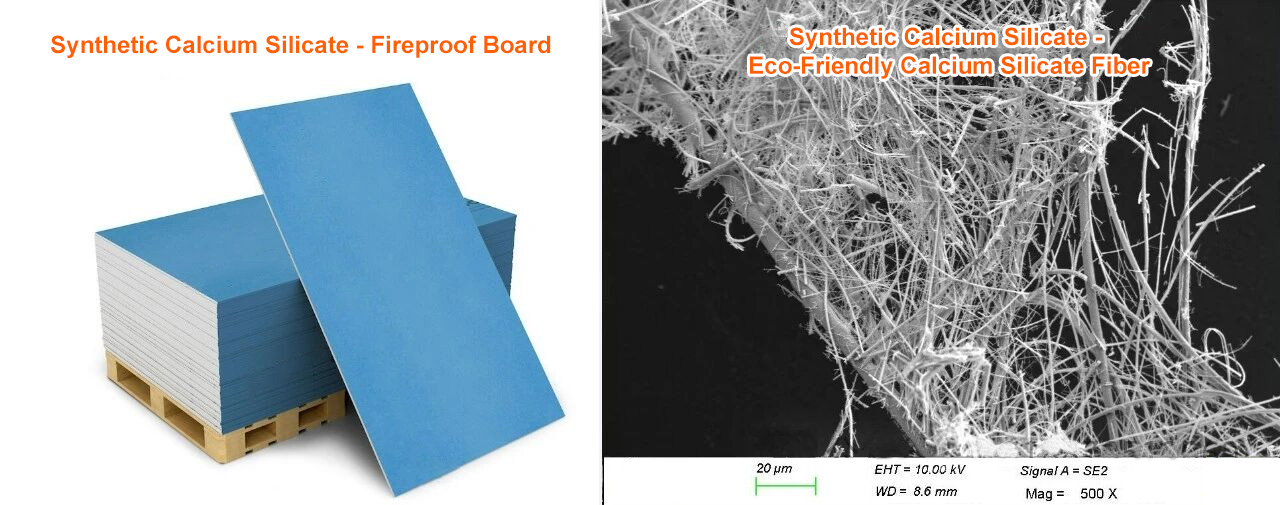

I-calcium silicate yokwenziwa ikhona ngezindlela ezimbili: izakhiwo ezinezimbobo/eziyindilinga kanye nezakhiwo ezine-fiber efana ne-ceramic. Naphezu kokwehluka kwezakhi kanye nokwakheka, zombili zisebenza njengezinto zokugcwalisa ezimhlophe ezivikela ukushisa ezimelana nokushisa okuphezulu.

I-fibre ye-calcium silicate yokwenziwa iyi-fiber enobungani nemvelo futhiizinto zokuvikela ukushisa eziphephileenokumelana nokushisa okuphezulu kuze kufike ku-1200-1260°C. Impuphu ye-calcium silicate fiber eyenziwe ngokukhethekile ingasebenza njengento eqiniswe yi-fiber yokuvikela ukushisa okuphezulu.

I-calcium silicate yokwenziwa enezimbobo noma eyindilinga, okwamanje, inobumhlophe obuphezulu, kulula ukuyihlanganisa, isakhiwo esicebile se-nanoporous, amanani aphezulu kakhulu okumunca uwoyela (afika ku-400 noma ngaphezulu), kanye nokukhululeka kumabhola e-slag noma izinhlayiya ezinkulu. Ifakazele ukusetshenziswa ekufakweni kokushisa okuphezulu kanye namaphaneli angashisi, okubonisa ukuthi kungenzeka ukufakwa ezintweni ezimelana nokushisa okuphezulu ukuze kuhlinzekwe ngokushisa okuphezulu.

Ezinye izinhlelo zokusebenza zifaka: izithasiselo zoketshezi oluyimpuphu, izembozo zempuphu ezivikela ukushisa okuphezulu, izithwali zokungenisa amakha, ama-anti-drip agents, izinto zokungqubuzana kwephedi yamabhuleki, irabha ye-silicone enomfutho ophansi kanye namafutha e-silicone azibolayo, ama-filler ephepha, njll.

2. I-Magnesium Aluminium Silicate Enezimbobo Ezinezingqimba- Ukushisa Okushisayo Nokumelana Nokushisa Okuphezulu

Le minerali ye-silicate idinga i-calcination eshisa kakhulu enokumelana nokushisa okufika ku-1200°C. Yakhiwe ngokuyinhloko nge-magnesium aluminium silicate, inesakhiwo esicebile esinezimbobo esihlinzeka ngamandla aphezulu okubopha, ukumelana namanzi okuhle kakhulu, isikhathi eside sokungamelani nokumelana, kanye nokusebenza kahle kwezindleko.

Imisebenzi yayo eyinhloko ifaka phakathi ukuvikela ukushisa okuphezulu, ukunciphisa ubuningi, ukuqina kokumelana nokushisa, kanye nokumelana nokushisa okuthuthukisiwe kanye nokuvikela ukushisa kwezingqimba zekhabhoni kanye nezimbobo. Izicelo zifaka phakathi izinto zokuvikela ezenziwe nge-ceramic, izembozo ezivikela umlilo zekhwalithi ephezulu, izinto zokuvikela ukufudumala ezimelana nokushisa, kanye nezinto zokuvikela ukushisa ezimelana nokushisa.

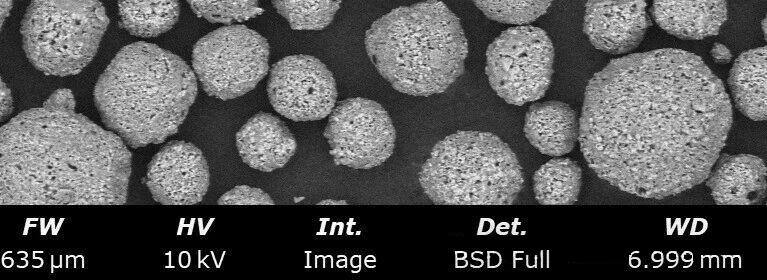

3. Ama-Microspheres e-Ceramic – Ukumelana Nokushisa Okuphezulu, Ukufakwa Kokushisa, Amandla Okucindezela

Ama-microsphere engilazi angenalutho ngokungangabazeki ayizinto ezinhle kakhulu zokuvikela ukushisa, kodwa ukumelana kwawo nokushisa akwanele. Amaphuzu awo okuthambisa ngokuvamile asukela ku-650-800°C, kanti amazinga okushisa okuncibilika angu-1200-1300°C. Lokhu kunciphisa ukusetshenziswa kwawo ezimweni zokuvikela ukushisa ezisezingeni eliphansi. Ngaphansi kwezimo zokushisa eziphakeme njengokwakhiwa kwe-ceramic kanye nokumelana nokukhishwa kwe-ablation, awasebenzi.

Ama-microsphere ethu e-ceramic angenalutho axazulula le nkinga. Akhiwe ngokuyinhloko nge-aluminosilicate, anikeza ukumelana nokushisa okuphezulu, ukuvikela ukushisa okuvelele, ukumelana nokushisa okuphezulu, kanye nokumelana nokuqhekeka okuphezulu. Izicelo zifaka izithasiselo ze-silicone ceramic, izinto zokuvikela ukufudumala eziphikisayo, izithasiselo zokushisa okuphezulu zama-resin e-organic, kanye nezithasiselo zerabha ezimelana nokushisa okuphezulu. Imikhakha ebalulekile ihlanganisa izindiza, ukuhlola okujulile kolwandle, izinto ezihlanganisiwe, ukumbozwa, ukuvikela ukufudumala okuphikisayo, imboni kaphethiloli, kanye nezinto zokuvikela.

Lena yi-micropowder eyindilinga engenalutho engashisi kakhulu futhi okulula kakhulu ukuyifaka (ngokungafani nama-microsphere engilazi angenalutho, adinga ukuhlakazwa noma ukuguqulwa ngaphambi kokufakwa okufanele) futhi abonisa ukumelana okuhle kakhulu kokuqhekeka. Isici sayo esihlukile ukuthi iyinto evulekile ebusweni engantanti emanzini, okwenza kube lula ukuyijiya nokuhlala.

Ngaphezu kwalokho, ukukhulunywa kafushane ngeimpuphu ye-airgel—into yokufakelwa yokuvikela i-silica enezimbobo. I-Aerogel yaziwa kabanzi njengesivikelo esihle kakhulu sokushisa, esitholakala ngezinhlobo ze-hydrophobic/hydrophilic. Lokhu kuvumela ukukhethwa kwezindlela zokwelapha ezifanele ngokusekelwe kuma-substrates e-resin, ukubhekana nezinselele ze-aerogel powder zokusabalala okulula kakhulu nokuthuthukisa ukuhlakazeka kwayo. Ama-paste e-aerogel asekelwe emanzini nawo ayatholakala ukuze afakwe kalula ezinhlelweni zamanzi.

Izakhiwo eziyingqayizivele zokuvimbela ukushisa ezinezimbobo zempuphu ye-aerogel zivumela ukusetshenziswa kwayo ku: – Izithwali zenjoloba nezepulasitiki – Izinto zokuvimbela ukushisa zamabhethri amasha amandla – Izembozo zokuvimbela ukwakha – Imicu yendwangu yokuvimbela ukushisa – Amaphaneli okuvimbela ukwakha – Izembozo zokuvimbela ukushisa ezingashi – Izinamathiseli zokuvimbela ukushisa.

Isikhathi sokuthunyelwe: Septhemba-22-2025