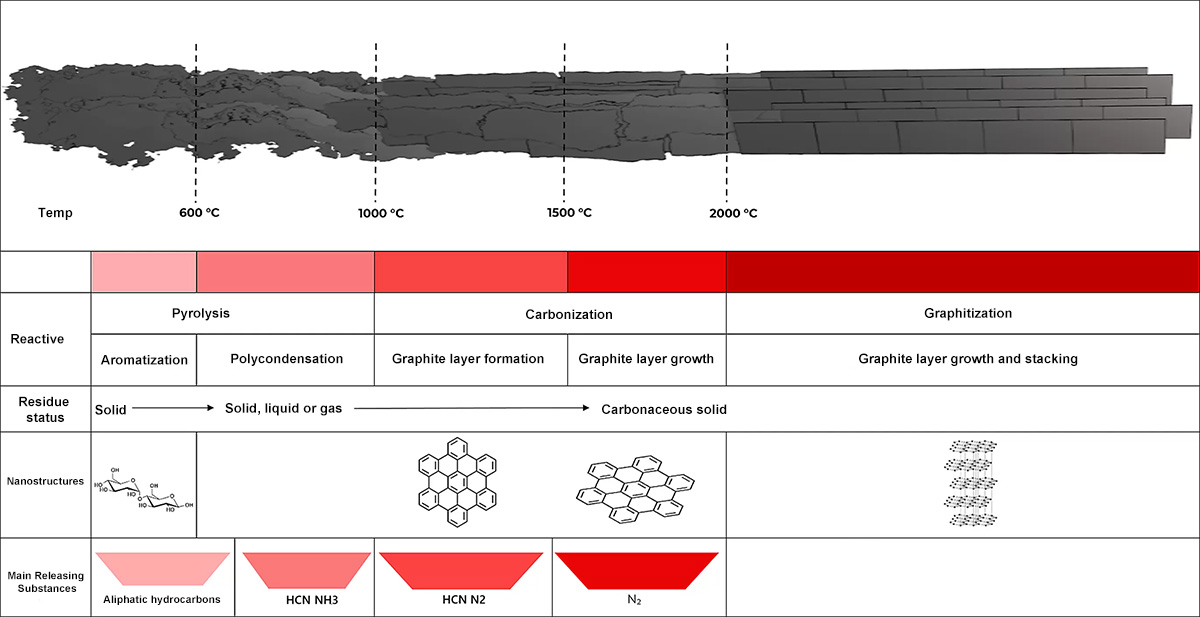

Izintambo ezingavuthiwe ezisekelwe ku-PAN zidinga uku-oxidized kusengaphambili, zi-carbonized ezisezingeni eliphansi lokushisa, futhi zi-carbonized ezisezingeni eliphezulu lokushisa ukuze zakheke.imicu yekhabhoni, bese kwenziwa i-graphit ukuze kwenziwe imicu ye-graphite. Izinga lokushisa lifinyelela kusuka ku-200℃ kuya ku-2000-3000℃, okwenza ukusabela okuhlukile futhi kwakha izakhiwo ezihlukene, ezibuye zibe nezakhiwo ezihlukile.

1. Isigaba se-pyrolysis:Ukufakwa kwe-oxidation engxenyeni enezinga lokushisa eliphansi, ukufakwa kwe-carbonization emazingeni okushisa aphansi engxenyeni enezinga lokushisa eliphezulu

I-arylation yangaphambi kokuxiliswa kwenzeka, ubude bayo bucishe bube yimizuzu eyi-100, izinga lokushisa liyi-200-300 ℃, inhloso iwukuba i-thermoplastic PAN linear macromolecular chain ibe yisakhiwo se-trapezoidal esimelana nokushisa esingeyona ipulasitiki, ukusabela okuyinhloko kwe-macromolecular chain ye-cyclization kanye ne-intermolecular crosslinking, ehambisana nokusabela kwe-pyrolysis kanye nokukhululwa kwama-molecule amaningi amancane. Inkomba ye-arylation ngokuvamile ingu-40-60%.

Izinga lokushisa eliphansi le-carbonizationngokuvamile ingu-300-800 ℃, ikakhulukazi ukusabela kokuqhekeka kokushisa, ikakhulukazi kusetshenziswa ukushisa kwentambo yesithando sikagesi esishisayo kakhulu, isiteji sikhiqiza inani elikhulu legesi yokukhipha kanye netiyela,.

Izici: Umbala wefayibha efakwe i-oxid uzoba mnyama, ngokuvamile umnyama, kodwa usalokhu ugcina isimo sefayibha, isakhiwo sangaphakathi sidlule ezingeni elithile lezinguquko zamakhemikhali, ukwakheka kwamaqembu amaningi asebenzayo aqukethe umoya-mpilo kanye nesakhiwo esixhumanisayo, okubeka isisekelo se-carbonization elandelayo.

2. Isigaba sokwenziwa kwe-carbon (esiphezulu), kunguku-oxidation kwesandulela esimweni esingenawo umoya lapho kubola khona izinga lokushisa eliphezulu, ukususwa kwaso ngaphezu kwama-heteroatom e-carbon (njenge-oxygen, i-hydrogen, i-nitrogen, njll.), ukuze i-carbonization iqhubeke kancane kancane, ukwakheka kwe-carbon amorphous noma isakhiwo se-microcrystalline carbon. Le nqubo iyisinyathelo esibalulekile ekwakhekeni kwe-carbon skeleton. Izinga lokushisa ngokuvamile liphakathi kuka-1000-1800 ℃, ikakhulukazi ukusabela kokushisa, iningi lama-heater e-graphite asetshenziselwa ukushisa.

Izici: Ingxenye eyinhloko yezinto ezifakwe i-carbon yi-carbon, isakhiwo singu-carbon amorphous kakhulu noma isakhiwo se-graphite esingenasiphene, ugesi waso oqhuba, izakhiwo zawo zemishini uma kuqhathaniswa nomkhiqizo we-pre-oxidation unezinga elikhulu lokukhula.

3. Ukuhlelwa kwe-graphitizationkuyindlela yokwelapha ukushisa eyengeziwe yemikhiqizo yokwenza i-carbonization emazingeni okushisa aphezulu ukukhuthaza isakhiwo se-carbon amorphous noma i-microcrystalline carbon esakhiweni sekristalu se-graphite esihlelekile. Ngesenzo sokushisa okuphezulu, ama-athomu e-carbon ahlelwa kabusha ukuze akhe isakhiwo sengqimba ye-lattice enezinhlangothi eziyisithupha enezinga eliphezulu lokuma, ngaleyo ndlela kuthuthukiswe kakhulu ukuhanjiswa kukagesi nokushisa kanye namandla omshini wezinto.

Izici: Umkhiqizo ofakwe i-graphit unesakhiwo se-graphite esicwebezelayo kakhulu, esihlinzeka ngogesi nokushisa okuhle kakhulu, kanye namandla aphezulu athile kanye ne-modulus ethile. Isibonelo, i-modulus ephezuluimicu yekhabhonizitholakala ngezinga eliphezulu le-graphitization.

Izinyathelo ezithile kanye nezidingo zemishini yokulungiselela i-pre-oxidation, i-carbonization kanye ne-graphitization:

Ukufakwa kwe-oxidation ngaphambi kokusetshenziswa kwe-oxidation: kwenziwa emoyeni ezingeni lokushisa elilawulwayo elingu-200-300°C. Ukucindezeleka kudinga ukusetshenziswa ukuze kuncishiswe ukuncishiswa kwe-fiber.

Ukwenziwa kwe-carbonization: kwenziwa endaweni engasebenzi kahle enokwenyuka kancane kancane kwezinga lokushisa kuya ku-1000-2000°C.

Ukwenziwa kwe-graphitization: kwenziwa emazingeni okushisa aphezulu (2000-3000°C), ngokuvamile endaweni evalekile noma endaweni engasebenzi kahle.

Isikhathi sokuthunyelwe: Meyi-22-2025