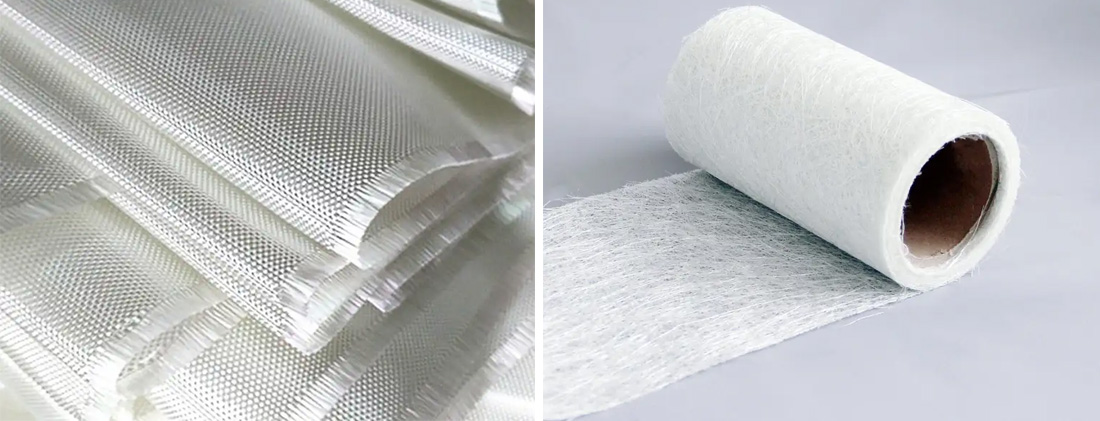

Ama-Glass Fiber Mata

1.Uhlaka Oluqoshiwe Lwezinsika (CSM)Ukuhambahamba ngefayibha yengilazi(ngezinye izikhathi futhi izulazula njalo) inqunywa ibe ubude obungu-50mm, ibekwe ngokungahleliwe kodwa ngendlela efanayo ebhandeni le-conveyor mesh. I-emulsion binder ibe isisetshenziswa, noma i-powder binder ifafazwa phezu kwayo, bese izinto ziyashiswa futhi zilungiswe ukuze kwakhiwe uhlaka lwezintambo oluqoshiwe. I-CSM isetshenziswa kakhulu ekubekeni ngesandla, ekwenzeni amaphaneli okuqhubekayo, ekubumbeni okufanisiwe, kanye nezinqubo ze-SMC (Sheet Molding Compound). Izidingo zekhwalithi ze-CSM zifaka:

- Isisindo sendawo efanayo ububanzi.

- Ukusatshalaliswa okufanayo kwemicu eqoshiwe ebusweni bomatilasi ngaphandle kwezikhala ezinkulu, kanye nokusatshalaliswa okufanayo kwesibopho.

- Amandla omathi owomile aphakathi nendawo.

- Izakhiwo ezinhle kakhulu zokumanzisa i-resin kanye nokungena kwayo.

2.Uhlaka lwentambo oluqhubekayo (CFM)Izintambo zefayibha yengilazi eziqhubekayo ezakhiwe ngesikhathi senqubo yokudweba noma ziqaqelwa emaphaketheni ajikelezayo zibekwe phansi ngephethini engu-figure-eight ebhandeni le-mesh elihamba njalo futhi ziboshwe nge-powder binder. Njengoba izintambo ku-CFM ziqhubeka njalo, zinikeza ukuqinisa okungcono ezintweni ezihlanganisiwe kune-CSM. Isetshenziswa kakhulu ezinqubo ze-pultrusion, i-RTM (Resin Transfer Molding), i-pressure bag molding, kanye ne-GMT (Glass Mat Reinforced Thermoplastics).

3.Uhlaka LokumbozaImikhiqizo ye-FRP (Fiber Reinforced Plastic) imvamisa idinga ungqimba olungaphezulu olucebile nge-resin, oluvame ukutholakala kusetshenziswa ungqimba oluphezulu lwengilazi ephakathi ne-alkali (C-glass). Njengoba lo mati wenziwe ngengilazi ye-C, unikeza i-FRP ukumelana namakhemikhali, ikakhulukazi ukumelana ne-asidi. Ngaphezu kwalokho, ngenxa yobuncane bayo nobubanzi befayibha obuncane, ingamunca i-resin eningi ukuze yakhe ungqimba olucebile nge-resin, imboze ukuthungwa kwezinto zokuqinisa ifayibha yengilazi (njengokuzulazula okulukiwe) futhi isebenze njengokuqeda ubuso.

4.Uhlaka OlunenalitiIngahlukaniswa nge-Chopped Fiber Needled Mat kanye ne-Continuous Filament Needled Mat.

- Uhlaka Olune-Fiber Oluqoshiwe Olune-NeedledKwenziwa ngokusika i-fiber yengilazi ibe ubude obungu-50mm, uyibeke ngokungahleliwe ku-substrate eyayibekwe ngaphambili ebhandeni lokuhambisa, bese uyifaka ngezinaliti ezinezinti. Izinaliti zisunduza imicu eqoshiwe ku-substrate, kanti nezinti nazo ziletha imicu ethile, zakha isakhiwo esinezilinganiso ezintathu. I-substrate esetshenziswayo ingaba yindwangu elukiwe kancane yengilazi noma eminye imicu. Lolu hlobo lwe-needled mat lunokuthungwa okufana nokuzwakala. Ukusetshenziswa kwalo okuyinhloko kufaka phakathi izinto zokushisa nezokushisa ezisebenza ngokushisa, izinto zokufaka ulwelwesi, nezinto zokuhlunga. Ingasetshenziswa futhi ekukhiqizweni kwe-FRP, kodwa i-FRP ephumayo inamandla aphansi kanye nobubanzi bokusetshenziswa obulinganiselwe.

- Intambo Eqhubekayo Enenaliti MatKwenziwa ngokuphonsa ngokungahleliwe imicu yefayibha yengilazi eqhubekayo ebhandeni eliqhubekayo le-mesh kusetshenziswa idivayisi yokusabalalisa imicu, kulandelwe ukufakwa ngenaliti ngebhodi lenaliti ukuze kwakhiwe umata onesakhiwo sefayibha esihlanganisiwe esinezinhlangothi ezintathu. Lo mata usetshenziswa kakhulu ekukhiqizweni kwamashidi e-thermoplastic aqiniswe ngefayibha yengilazi.

5.Uhlaka OluthungiweImicu yengilazi eqoshiwe esukela ku-50mm kuya ku-60cm ubude ingathungwa kanye nomshini wokuthunga ukuze kwakhiwe umata we-fiber oqoshiwe noma umata we-fiber omude. Owokuqala ungathatha indawo ye-CSM yendabuko eboshwe nge-binder kwezinye izinhlelo zokusebenza, kanti owesibili, ngezinga elithile, ungathatha indawo ye-CFM. Izinzuzo zabo ezivamile ukungabikho kwama-binder, ukugwema ukungcola ngesikhathi sokukhiqizwa, ukusebenza kahle kwe-resin impregnation, kanye nezindleko eziphansi.

Izindwangu Ze-Glass Fiber

Okulandelayo kwethula izindwangu ezahlukahlukene zefayibha yengilazi ezilukiwe kusukaizindwangu zefayibha yengilazi.

1. Indwangu YengilaziIndwangu yengilazi ekhiqizwa eShayina ihlukaniswe ngezinhlobo ezingenayo i-alkali (i-E-glass) kanye nezinhlobo eziphakathi nendawo (i-C-glass); iningi lemikhiqizo yangaphandle isebenzisa indwangu yengilazi engenayo i-E-GLASS alkali. Indwangu yengilazi isetshenziswa kakhulu ukukhiqiza ama-laminate ahlukahlukene kagesi okuvikela ukushisa, amabhodi wesekethe aphrintiwe, imizimba yezimoto, amathangi okugcina, izikebhe, isikhunta, njll. Indwangu yengilazi ephakathi nendawo isetshenziswa kakhulu ukukhiqiza izindwangu zokupakisha ezimbozwe ngepulasitiki kanye nezinhlelo zokusebenza ezingagqwali. Izici zendwangu zinqunywa yizakhiwo zefayibha, ubuningi be-warp kanye ne-weft, isakhiwo sentambo, kanye nephethini yokweluka. Ubuningi be-warp kanye ne-weft bunqunywa yisakhiwo sentambo kanye nephethini yokweluka. Ukuhlanganiswa kobukhulu be-warp kanye ne-weft kanye nesakhiwo sentambo kunquma izakhiwo zomzimba zendwangu, njengesisindo, ukujiya, kanye namandla okuphuka. Kunezindlela ezinhlanu eziyisisekelo zokweluka: ezicacile (ezifana nokweluka okulukiwe), i-twill (ngokuvamile ± 45°), i-satin (efana nendwangu eqondene ne-unidirectional), i-leno (ukweluka okuyinhloko kwe-glass fiber mesh), kanye ne-matts (efana nendwangu ye-oxford).

2.Itheyiphu Yefayibha YengilaziIhlukaniswe ngeteyipu enomphetho othungiwe (umphetho we-selvage) kanye neteyipu enomphetho ongelukiwe (umphetho oqhekeziwe). Iphethini eyinhloko yokweluka ilula. Iteyipu yefayibha yengilazi engena-alkali ivame ukusetshenziselwa ukukhiqiza izingxenye zemishini kagesi ezidinga amandla aphezulu kanye nezakhiwo ezinhle ze-dielectric.

3.Indwangu Ye-Glass Fiber Eqondiswe Ngandlela-thile

- Indwangu Egobile Engaqondileiyindwangu ye-satin ephukile enama-harness amane noma indwangu ye-satin ende elukiwe ngezintambo ze-warp eziqinile kanye nezintambo ze-weft ezincane. Isici sayo amandla aphezulu ikakhulukazi ohlangothini lwe-warp (0°).

- Kukhona futhiIndwangu Ye-Glass Fiber Engaqondisiwe Kakhulu, itholakala kokubili ngezinhlobo ezilukiwe nge-warp kanye nezinhlobo ezilukiwe. Ibonakala ngezintambo ze-weft eziqinile kanye nezintambo ze-warp ezincane, kanye nezintambo ze-glass fiber eziqondiswe kakhulu ohlangothini lwe-weft, ezinikeza amandla aphezulu ohlangothini lwe-weft (90°).

4.Indwangu ye-Glass Fiber 3D (Indwangu ye-Stereoscopic)Izindwangu ze-3D zihlobene nezindwangu ezihleliwe. Izici zazo zesakhiwo zishintshe kusukela kobukhulu obubodwa nobukhulu obubili kuya kobukhulu obuthathu, okunikeza izinto ezihlanganisiwe eziqiniswe yizo ubuqotho obuhle kanye nokuhambisana kwazo, okuthuthukisa kakhulu amandla okusika phakathi kwe-laminar kanye nokubekezelelana komonakalo kwezinhlanganisela. Zenzelwe ukuhlangabezana nezidingo ezikhethekile zezindiza, izindiza, izikhali, kanye nemikhakha yasolwandle, futhi ukusetshenziswa kwazo manje sekukhule ukuze kufake phakathi izimoto, izimpahla zezemidlalo, kanye nemishini yezokwelapha. Kunezigaba ezinhlanu eziyinhloko: izindwangu ze-3D ezilukiwe, izindwangu ze-3D ezilukiwe, izindwangu ze-3D ezingezona ezigobile nezingezona ezigobile, izindwangu ezilukiwe ze-3D, kanye nezinye izinhlobo zezindwangu ze-3D. Izimo zezindwangu ze-3D zifaka phakathi i-block, i-columnar, i-tubular, i-hollow truncated cone, kanye nezingxenye ezingavamile zokujiya okuguquguqukayo.

5. Indwangu Yokulungisa I-Glass Fiber (Indwangu Ebunjiwe)Ukuma kwezindwangu ezisalungiswa kufana kakhulu nokuma komkhiqizo ezihloselwe ukuwuqinisa, futhi kumele zilukwe ezindwangu ezikhethiwe. Izindwangu ezimise okwesimethri zifaka: izigqoko eziyindilinga, amakhoni, izigqoko, izindwangu ezimise okwesimethri, njll. Kungakhiqizwa nokuma okungalingani njengamabhokisi namagobolondo esikebhe.

6.Indwangu Eyinhloko Ye-Glass Fiber (Indwangu Yokuthunga Enobukhulu Obuthile)Indwangu eyinhloko inezendlalelo ezimbili ezihambisanayo zendwangu ezixhunywe ngemicu eqondile ende. Isimo sayo esiphambene singaba unxantathu, unxande, noma uju lwezinyosi.

7.Indwangu Eboshwe Nge-Glass Fiber (Umati Othungiwe noma Umati Olukiwe)Ihlukile ezindwangu ezivamile kanye nomqondo ojwayelekile womathe. Indwangu eboshwe ngomthungo evamile yakhiwa ngokumboza ungqimba olulodwa lwentambo egoqekile kanye nongqimba olulodwa lwentambo egoqekile, bese izithunga ndawonye ukuze zakhe indwangu. Izinzuzo zezindwangu eziboshwe ngomthungo zifaka:

- Kungakhulisa amandla okuqina okuqinile, amandla okulwa nokwehliswa kwe-delamination ngaphansi kokucindezeleka, kanye namandla okuguquguquka kwama-laminate e-FRP.

- Kunciphisa isisindo seImikhiqizo ye-FRP.

- Ubuso obuyisicaba benza ubuso be-FRP bube buthambile.

- Kwenza kube lula ukusebenza kokubeka izandla futhi kuthuthukise umkhiqizo wabasebenzi. Lokhu kuqinisa izinto kungathatha indawo ye-CFM ku-FRP kanye ne-RTM ehlanganisiwe, futhi kungathatha indawo yokujikeleza okulukiwe ekukhiqizweni kwamapayipi e-FRP ahlanganisiwe.

Isikhathi sokuthunyelwe: Okthoba-22-2025